A company that offers prototyping, part design services, quick response manufacturing, and in-depth mold flow analysis creates valuable efficiencies within project timelines. This is especially important in the early design process, where the most significant cost and time savings can be realized.

Having a molder who can make recommendations without sacrificing specifications puts product manufacturers in a stronger position to get to market quickly.

Experience

A trustworthy plastic injection molding company will be able to create valuable cost and time efficiencies throughout the entire project process. They can do so by proactively becoming involved in the design process and understanding your objectives early on.

They will also be able to offer value-added services like rapid response manufacturing, in-depth mold flow analysis, and more. This is a great way to avoid expensive engineering changes down the road and ensure that your project stays on budget.

They will have a proven track record of producing quality molded parts at competitive prices. They will also be able to run two-shot injection molding, which involves injecting two different materials into the same mold in one manufacturing cycle. This reduces stress and surface imperfections.

Technology

The latest technology helps set premier injection mold manufacturers apart from their competitors. These advanced processes allow them to deliver a superior turn-around time and quality.

Injection molding utilizes a high-pressure, three-dimensional plastic part that is molded into the shape of the desired product. The resulting product has a uniform configuration from copy to copy, an advantage over other manufacturing methods.

A reputable premier injection manufacturer also has in-house tooling capabilities, which reduces lead times. They can machine your molds in-house, allowing them to control the project’s progress and schedule. They also understand the impact of resin rate and can offer helpful suggestions to help you save money on your production run. They can even suggest cost-effective alternative materials that deliver the same performance as premium plastic.

Flexibility

A premier injection mold manufacturer should be able to offer a wide variety of services that span the entire life cycle of a project. Access to prototyping, part design services, rapid response manufacturing, and in-depth mold flow analysis will help create valuable cost and timing efficiencies with your project.

Much of the injection molding process is automated by machines and robots that a single operator can control and manage, streamlining labor costs and saving production time. High-strength, lightweight thermoplastics can replace metal parts in many circumstances without sacrificing strength or dependability.

An excellent injection molding company will communicate lead times and allow customers to prepare in advance for unexpected delays due to supply chain issues. They will also try to meet and exceed the customer’s quality expectations.

Reliability

Injection molding is a complex process. Several potential challenges can arise, including delays due to weather-related disasters and global events that disrupt supply chains. Choosing a plastic injection mold partner with a proven track record of reliability can help you avoid delays and meet production goals.

In addition to timely delivery, finding a premier plastic injection mold manufacturer that offers quality assurance and transparency throughout the repair process is also essential. This helps ensure that all repairs are made correctly and efficiently, minimizing downtime and improving productivity.

A qualified plastic injection molding company should have a system for communicating timelines with clients. This starts with an initial agreement about timelines and expectations at the beginning of the project. This reduces the risk of misunderstandings that could lead to costly delays.

Customer Service

The proper injection mold manufacturer doesn’t just produce parts. They also provide a wide range of services that help you get your project from concept to reality. For instance, they should be able to offer you advice about draft angles and undercuts to make your design more producible.

They provide advanced machinery, powerful staff, and cutting-edge technologies to ensure quality products that meet the needs of their clients. Their one-stop service and commitment to innovation have allowed them to earn clients’ trust worldwide.

A premier injection mold supplier can take your design from CAD to a finished product quickly and cost-effectively. They can also help you select the suitable materials for your application and deliver on time, every time.

More Stories

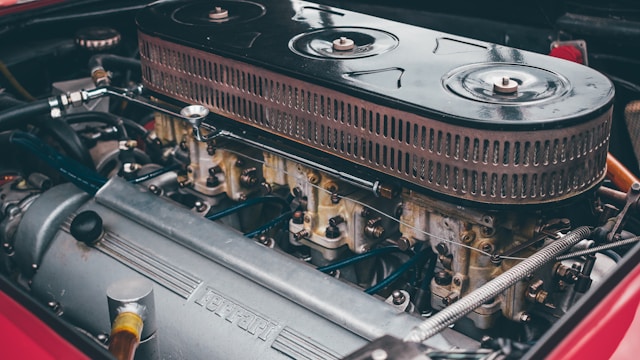

How Barrel Air Cleaners Improve Engine Performance: A Comprehensive Guide

Guarding Your Haven: The Essential Role of Regular Roof Inspections in Home Maintenance

Key to Success: How Online Piano Classes Can Transform Your Skills