When aircraft types go out of production, airlines and owners sometimes have to tear them down and market the individual components. This can be a valuable way to generate revenue from dormant inventory. Airframe parts consignment programs can help startup airlines avoid upfront costs, and small fleet operators reduce storage and shipping costs. When choosing a program, ask about its customer base and marketing strategies and how often it updates inventory reports in part locator services.

Lower Costs

Aircraft parts consignment allows operators to monetize their assets, freeing up valuable storage space in hangars. The key is working with a partner who can maximize return and minimize risk. The supplier should be able to show a detailed paper trail that addresses critical factors such as shipping costs, insurance coverage, and asset value.

A comprehensive part-out process will ensure that all components are sold at fair market value. The supplier will also be able to demonstrate back-to-birth commercial ownership traces on significant components and life-limited parts (LLPs). These measures will help reduce risk for reputational reasons and export control infractions.

Startup airlines or those with small fleets may avoid the upfront cost of acquiring and maintaining airframe spare parts inventories with a power-by-the-hour consignment program. Keeping these critical aircraft parts onsite for immediate availability helps lower costs and minimizes shipping costs. In addition, it increases operational efficiency and reduces Aircraft on-ground time.

Less Downtime

Aircraft parts consignment is a great way to convert spares into cash and free up space in hangars and warehouses. Parts & Rotables Sales experts help operators convert accessories, avionics systems, instruments, and components into cash while saving them valuable storage and shipping costs.

Many airlines and aircraft owners have dormant spare inventory. This may include avionics, black boxes, high-pressure turbines, and other parts with high-value or life-limited cycles (LLP). If these parts are not removed and sold, they are subject to disposal fees and can become an operational risk.

When choosing a consignment program, selecting one that physically maintains the inventory, has a comprehensive record of all parts, and provides 24/7 response to inquiries is essential. Ask your supplier about their customer base, marketing strategies, and consignment history. It would help if you also looked for a program that offers back-to-birth commercial ownership traces on all significant components and life-limited parts to ensure the integrity of your asset.

Faster Shipping

Aircraft parts consignment can reduce inventory management costs by enabling operators to pay for only the aircraft components they consume, saving on storage fees and eliminating the risk of obsolescence. Having spare parts onsite also speeds up repair time and minimizes shipping costs.

In addition to reducing upfront inventory costs, the aircraft parts consignment model can increase revenue through fast turnaround times and expedited processing and freight savings. Aircraft owners should choose a program that physically manages inventory and has back-to-birth commercial ownership traces on significant components and life-limited parts (LLPs) for reputational reasons and to mitigate exposure to export control infractions.

Many airlines participate in spare parts pooling to reduce the cost of stocking high-value components and ensure instant access to critical replacements. This results in less Aircraft on Ground (AOG) time. Parts pooling also helps reduce the cost of maintenance and repair by leveraging the serviceability of used serviceable parts salvaged from retired airplanes.

Increased Revenue

Aircraft parts consignment allows operators to avoid the upfront costs of purchasing extensive inventories and reduce carrying and storage fees by retaining inventory only for the specific items they consume. Having these parts on site minimizes shipping costs and helps them keep their fleet flying as quickly as possible.

However, owners must select a program that operates in their best interests. They should ensure that any program offers a back-to-birth commercial ownership trace on significant components and life-limited parts (LLPs) to protect their reputation and prevent export control infractions.

Some companies are helping airlines monetize their aging assets and turn unused and unwanted aircraft components into cash. However, they have a unique take on this as they pool their client’s aircraft assets into a single inventory sold to end users on a virtual consignment basis. This approach has reduced airline carrying costs, lowered stocking fees, and led to faster turnaround times and less Aircraft on Ground (AOG) time.

More Stories

Say Cheers to Time Saved: How Alcohol Delivery Services Make Your Life Easier

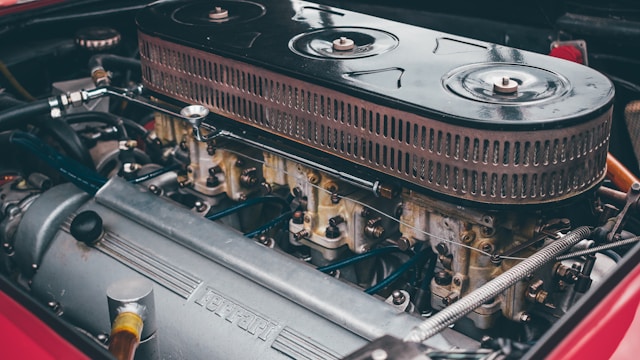

How Barrel Air Cleaners Improve Engine Performance: A Comprehensive Guide

Guarding Your Haven: The Essential Role of Regular Roof Inspections in Home Maintenance